Liquid Hydrogen

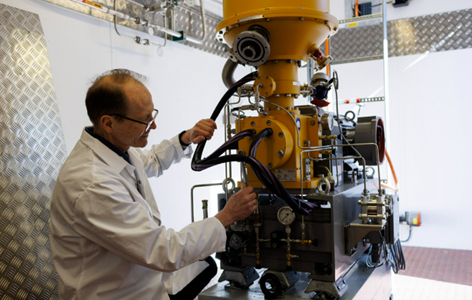

IFE has a long experience in the generation and use of liquid hydrogen (LH2), as an essential part of advanced instrumental setups at the JEEP-II neutron source at IFE, Kjeller. LH2 has been employed in a closed loop setup to moderate neutrons that were subsequently used in structure research on a wide range of materials. Based on this experience and knowledge gained over the years, IFE is now in the process of establishing a stand-alone installation for research and experiments related to liquid hydrogen. This will be an infrastructure encompassing hydrogen supply, liquefaction, (short-term) storage, as well as experimental test-bench, where a core part is a cryocooler unit combined with a specialized heat exchanger for liquefying hydrogen gas at low pressures (1-2 bar). Safety systems related to hydrogen in general together with the particular aspects of low-temperature cryogenics, are integral elements of the setup, incorporated already from the first design stage.

This LH2 laboratory will be used for developing new knowledge, technology and concepts related to liquid hydrogen as a high-density energy carrier. In addition to experiments, computer modelling (cf. CFD) is an important tool for exploring the properties of LH2 and predicting the behaviour in practical applications. IFE has different activities in this area, and experiments on liquid hydrogen will be highly important for gaining reference data and for optimization of computer models. The combination of experiments/tests and computer modelling will be essential for approaching a range of questions related to liquid hydrogen, for example concerning LH2-storage (thermal transport or liquid-gas dynamics/sloshing in tanks), flow in pipes and through orifices (relevant for LH2-bunkering), for studies of material integrity under long-term LH2-exposure, as well as for developing monitoring solutions connected with liquid hydrogen use (e.g. LH2 level sensors and flow meters).

IFE also has activities related to the improvement of the efficiency of the liquefaction process itself. Hydrogen liquefaction is currently a very energy-demanding process, and advances here will have significant impact on the cost of LH2 available on the market. The so-called magnetocaloric effect has great potential in this respect, and IFE has recently been granted a research project to work on this concept in collaboration with industry (cf. link below). A fully developed cooling unit based on magnetocalorics can be particulary relevant for maintenance cooling of for example small-/medium-sized LH2 storage tanks, due to absence of bulky compressor stages and the inherently low power consumption.

Laboratories

IFE Hynor Hydrogen Technology Center (IFE Hynor) – IFE

Links

Projects:

FME HYDROGENi – Norwegian research and innovation centre for hydrogen and ammonia

INDY, Energy Independent and Efficient Deployable Military Camps