Metal Hydrides

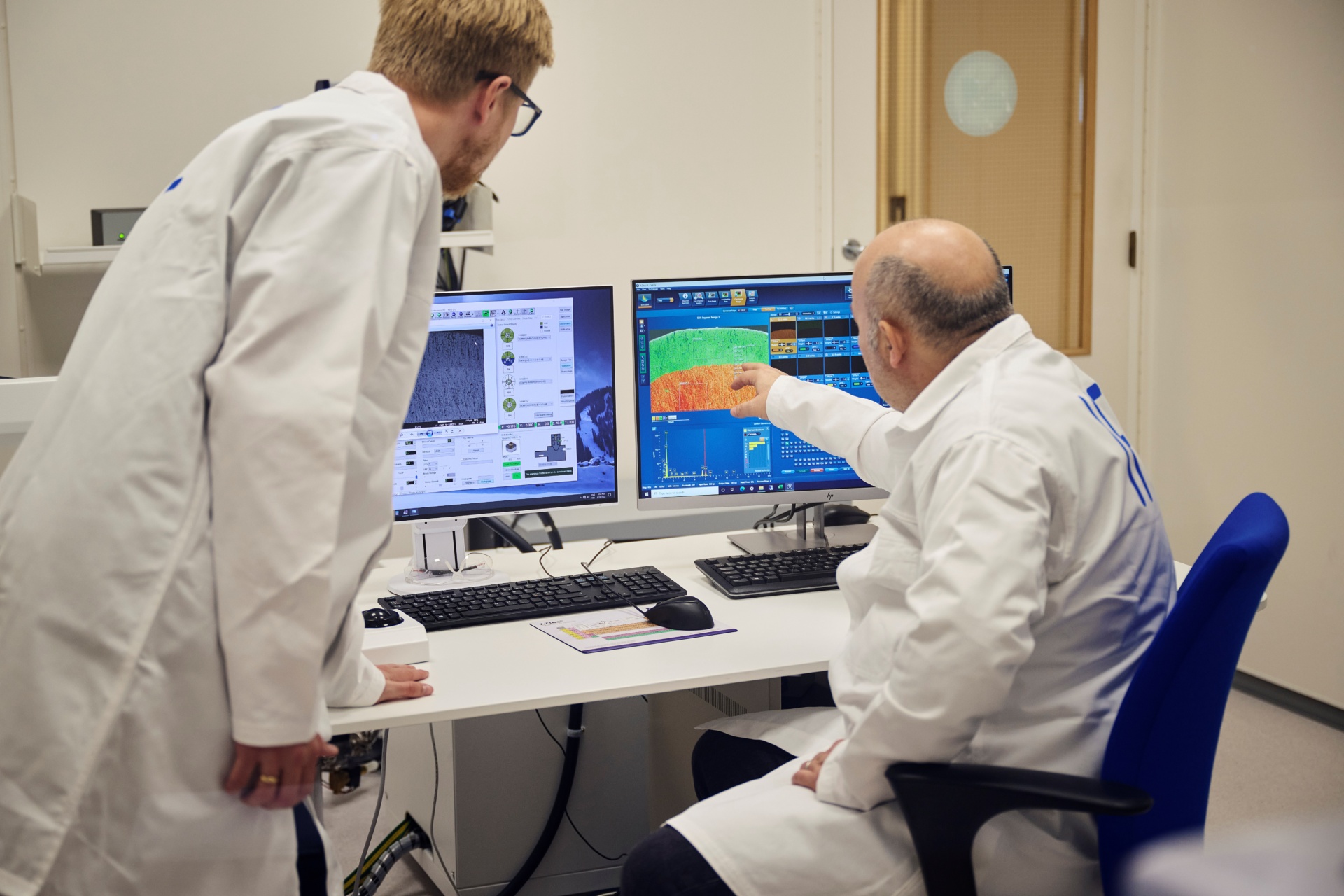

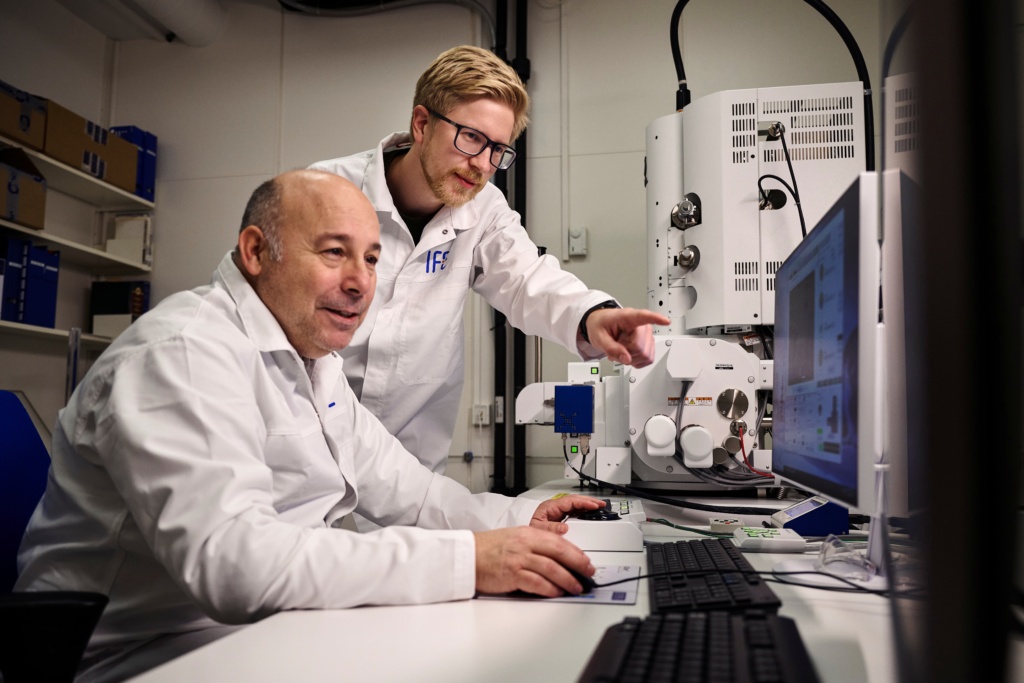

IFE have more than 70 years of experience on research on metal hydrides (MH). We have had most metal hydride EU-projects of any institution in Europe. The research is built upon our expert competence in materials development and characterisation especially based on a range of neutron scattering techniques for advanced material characterisation.

We combine the physical experiments with advanced modelling developed based on our experiments.

For just the last 20 years IFE have worked on more than 28 different metal hydrides. We are doing research towards

- Development of advanced new materials to improve the properties for storage of hydrogen for various applications

- Improve properties for system integration for various user cases taking into consideration various patterns of production, distribution, and most important different end user cases

- Document safety and properties needed for risk analysis

- Production of metal hydrides

Metal hydrides is the safest way to store hydrogen, since there is a need of adding heat to release hydrogen from the alloy and the hydrogen may be stored at low pressure and temperature. The area needed for safety zones and the extent of risk mitigation systems may be significantly reduced compared to compressed or liquid hydrogen storage. In many cases metal hydrides is the most cost-efficient way to store hydrogen since the storage materials in most cases have low cost and there is no need to compress or cool the hydrogen between production and storage. Metal hydrides is not the solution for weight sensitive applications, though the gravimetric energy density in average is twice the density of a lithium battery. Metal is hydrides is significantly more volume-efficient than hydrogen stored as compressed or liquid.

Projects:

FME HYDROGENi – Norwegian research and innovation centre for hydrogen and ammonia

INDY, Energy Independent and Efficient Deployable Military Camps