IFE Hynor Hydrogen Technology Center (IFE Hynor)

IFE Hynor Hydrogen Technology Center (IFE Hynor) is a fuel cell and hydrogen technology test center owned and operated by IFE.

IFE Hynor consists of the following research infrastructure:

- PEM Water Electrolyser System Laboratory (33 kW)

- PEM Fuel Cell System Laboratory (20 kW)

- Sorption Enhanced Reformer (SER) pilot plant (20 kg H2 /day)

- Liquid Hydrogen Experimental Setup

In addition, IFE Hynor includes the following infrastructure that can be used for this test campaigns:

- PV-system (16 kWp)

- Power conditioning systems (AC/DC, DC/AC)

- Gas supply and storage systems (H2, CH4, N2)

The IFE Hynor laboratories offer the possibility to perfrom research on water electrolysis and fuel cell stacks and systems. In addition to do experiments on the reforming of methane (CH4) rich gases to hydrogen (H2) with an integrated process for CO2-capture using a sorption enhanced reforming (SER) pilot plant. IFE Hynor also contain a laboratory setup for production and experimental work with liquid hydrogen (LH2). IFE Hynor is located at Kjeller, Norway.

The PEM Water Electrolyser and PEM Fuel Cell System Laboratories are part of the national research infrastructure The Norwegian Fuel Cell and Hydrogen Center

Water Electrolyser Testing

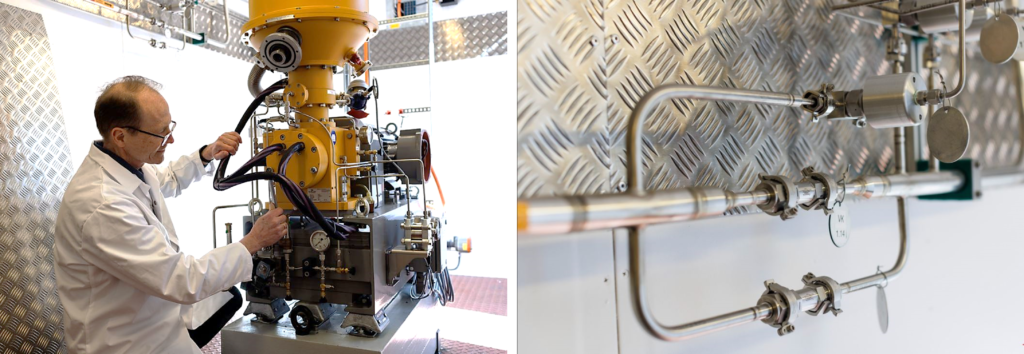

We provide the capability to validate the performance and durability of established water electrolysis technologies (short stacks) as well to test cutting edge electrolysis components (single cells). We currently operate two PEM water electrolysis test stations and one AEL testbench, and these are used for characterizing new electrolyser materials right through to developing advanced control strategies. Read more about our water electrolyser services here: Water Electrolysis – IFE

Photo: Greenlight E60 – PEM water electrolysis test station

Fuel Cell System

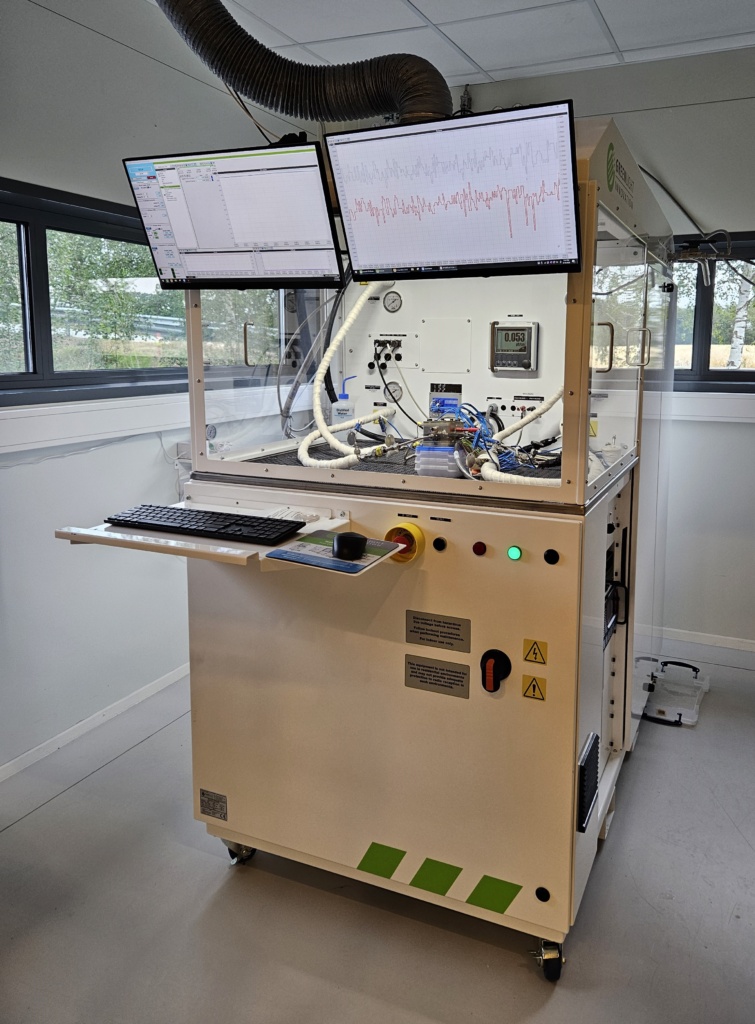

The fuel cell testing system is designed to test and validate low temperature PEM fuel cell stacks. It is possible to test both full stacks with smaller electrode areas (high voltage, low current), as well as short stacks with larger electrode areas (low voltage, high current), with power ratings up to 20 kW. The Balance of Plant (BoP) components for the fuel cell test rig, designed and built by IFE, includes a monitoring- and control system. Read more about our fuel cell testing capabiliteis here: Fuel Cell System – IFE

Customized Power System

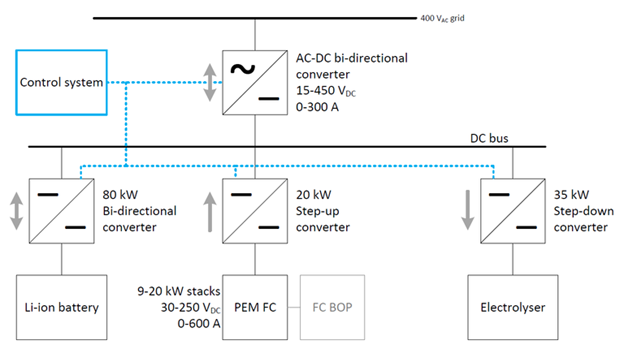

The PEM water electrolyser and fuel cell systems laboratories are connected to the same DC-bus via dedicated DC/DC converters (figure below). The DC/DC-converters are custom-made to provide a large flexibility with respect to input voltages and currents, making it possible to test many different types of units. The DC-bus is connected to the local grid via an AC/DC bidirectional converter, which can be programmed to emulate different types of loads or generators. The power conditioning system also includes a bi-directional DC/DC-converter to charge/discharge three Li-ion battery packs (type Dolphin ESS from Corvus Energy), each with a voltage of 115 VDC. The power system may also be connected to the 16 kWp PV-system.

System Applications

The flexible power system setup makes it possible to emulate the operation and performance of several different types of FCH power system applications. IFE is currently focusing on the following applications:

- Fuel cell power systems for heavy-duty applications (road, rail, and sea)

The laboratory can be used to emulate duty cycles (e.g. motors) and test corresponding performance of fuel cells, batteries, and hybrid fuel cell / battery system configurations. - Water electrolysis for renewable energy based power systems

The laboratory can be used to emulate duty cycles (e.g. grid load profiles, solar and/or wind generation) and test the performance of water electrolysers, batteries and hybrid system configurations .

More info about the Norwegian FCH research infrastructure project: The Norwegian Fuel Cell and Hydrogen Systems Laboratory (N-FCH) – IFE

SER proto type

IFE Hynor includes a Dual Bubbling Fluidized Bed reactor prototype (DBFB) for continuous hydrogen production with integrated CO2 capture via Sorption Enhanced Reforming (SER) or Sorption Enhanced Water-Gas Shift (SEWGS). The plant can operate with various feedstocks including biogas, natural gas, syngas from gasification/pyrolysis, as well as co-rich gases from smelters. Also, it is design in a versatile fashion and can be used to test catalyst and sorbent materials, as well as to explore the integration with fuel-cells, hydrogen compression systems and syngas producing reactors.

Current projects using IFE’s Hynor SER plant.

Liquid Hydrogen Experimental Setup

IFE Hynor contains a small-scale setup for production of liquid hydrogen (LH2) based on a Stirling-type cryomachine and a custom-made heat exchanger (cold-head). The equipment can conveniently be integrated into a complete LH2 experimental research infrastructure. This LH2 laboratory will then be used for developing new knowledge, technology and concepts related to liquid hydrogen as a high-density energy carrier. Experiments on liquid hydrogen can also be used as a basis for developing modelling tools for calculating properties (e.g., thermal transport) for LH2 storage tanks, for studies of material integrity under long-term LH2-exposure, as well as for developing monitoring solutions relevant for liquid hydrogen use.