The Flow Technology Department’s most significant contribution to society is the software simulator tool OLGA which today is commercialized by Schlumberger. This software tool has been branded “most important Norwegian innovation since 1980” (Aftenposten, 2012), and it contributed to savings on the Troll field alone of around 40-50 billion NOK and was an integral part of the development of subsea technology.

The department activities can broadly be split in two – mathematical modelling and experiments. We develop, or contribute to develop, simulator-software for companies of all sizes within the general field of Flow. Flow, in this case, can be anything from flow in aluminum-production, in blood vessels in the human body, in petroleum reservoirs and most types of process equipment.

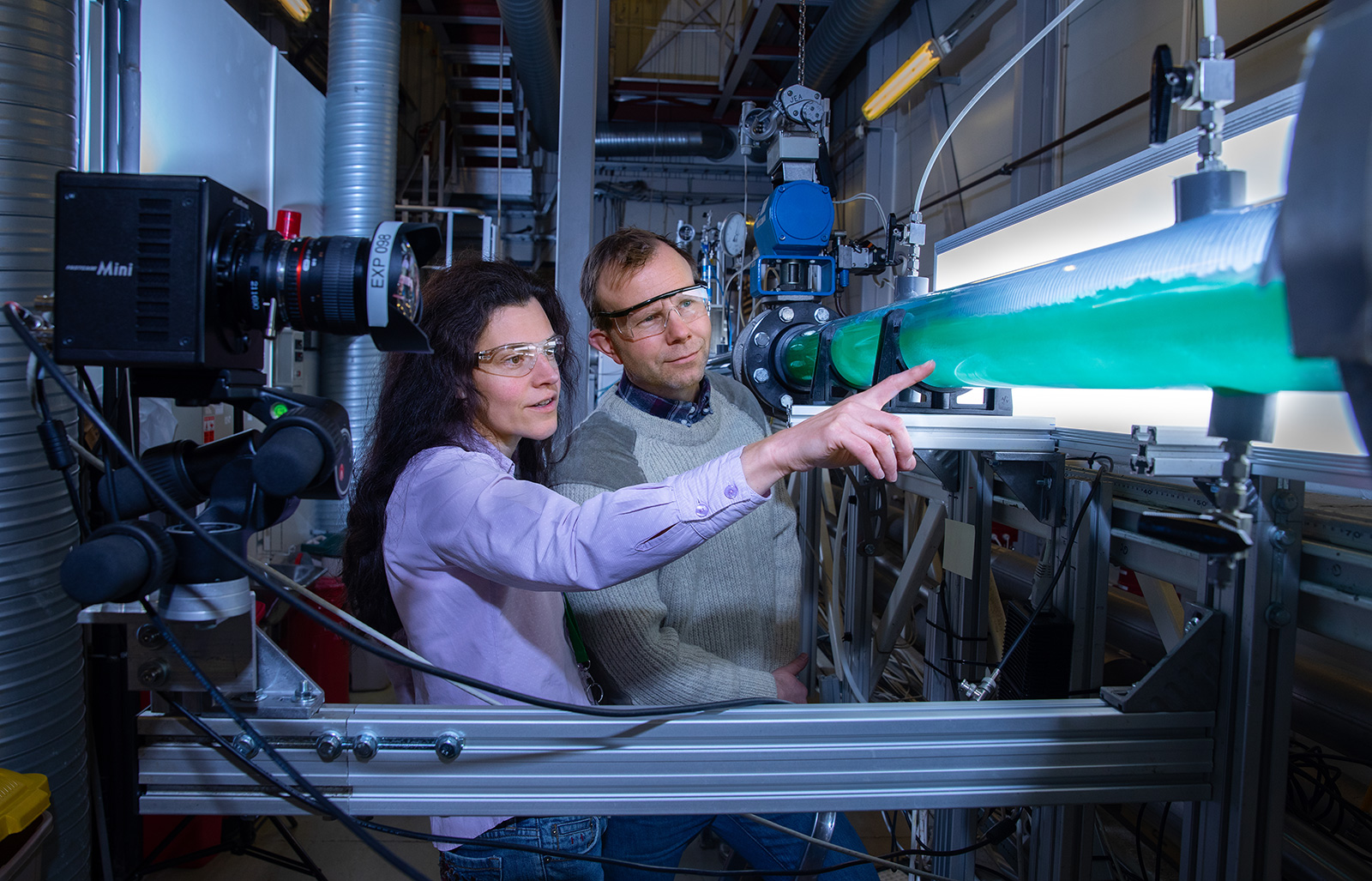

Our laboratories are firstly used to verify and improve simulator tools. Our largest laboratory, the Well Flow Loop, is also a part of the National Infrastructure for Multiphase Flows, and it is used by external companies of all sizes for equipment testing, development and demonstration. Vi operate 5 different laboratories which focus on multiphase flows, waxy oils, CO2-transport and so-called fluid-characterization (aka Rheology). We also build custom flow loops for our industry customers on a regular basis.

The core of our department is an ambitious group of problem solvers who continue to reach a little further and improve a little more. We are around 20 employees, many with PhD’s, and our backgrounds are from fields such as fluid mechanics, particle physics, applied mathematics, astrophysics, colloid chemistry and thermodynamics.

Our history is rooted in the fairy tale that is the Norwegian petroleum business, but our work has also always had a healthy focus on other flow related issues. Lately, we have seen a growing trend in health-related sciences (or life sciences). Today, several of our scientists are working on new tools for use in cancer treatment, including dosimetry calculations for alpha- and beta-emitting particles for “personalized medicine”. The latter sounds fancy, but basically implies that, based on a measurement such as MRI, we may tailor make individual treatment techniques to each patient and each tumor and predict the outcome in advance. In this way, the world benefits from Norwegian oil technology and competence for the second time.