Collaborative Decision Making using Diagnostic and Prognostic Reasoning

Collaborative Decision Making is an activity under the Halden Reactor Project focusing on using functional modelling techniques for analysis of physical processes. It has established the viability of using one such technique, multilevel flow modelling (MFM), for diagnostic and prognostic reasoning of anomalous process events (whether they are instrumentation/equipment malfunctions or process state changes).

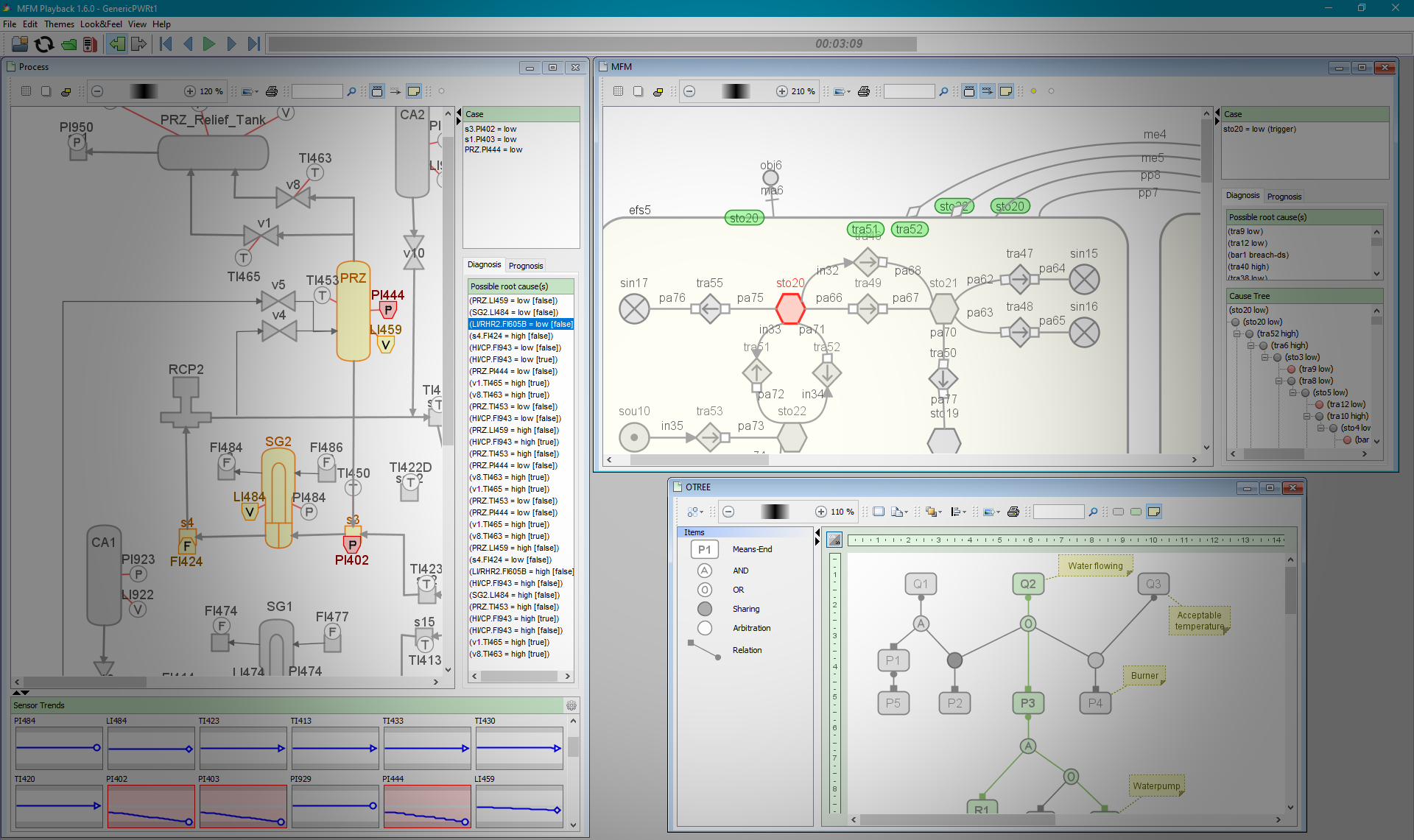

In MFM, the functionality of single process components or combinations of components are modelled using interconnected graphical symbols (MFM functions) that may exist in several distinct states. When encountering anomalous states, MFM provides reasoning about the possible causes and consequences.

As the control room and field operators should not be required to learn the intricacies of the MFM methodology and thus recognize the correlations between the MFM function states and process component conditions, the analysis results are displayed in a process-oriented format instantly recognizable and understandable to the operators.

Another focus of the activity is to suggest viable courses of action to the control room operators when possible causes and consequences have been determined. In addition, field operators should be able to quickly suggest or evaluate proposed actions. It should be verified that suggested actions are in accordance with established procedures.

Available tools

For the practical application of MFM, IFE has developed a suite of applications, the MFM Suite, to achieve the following goals:

- graphically design MFM and process models using drag-and-drop

- create necessary connections between the MFM and process models

- perform cause and consequence analyses on MFM models

- trace a process anomaly back to its root cause(s) or forward to its final consequence(s) and visualize this in the process model

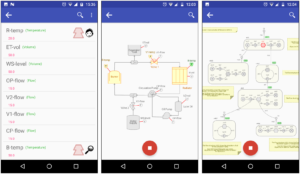

The MFM Suite furthermore allows external applications to request updated sensor and analysis data for subsequent visualization, and to transmit data back to the MFM Suite. One such application, the MFM Viewer for Android devices, has been specially developed to provide field operators with updated analysis data.

The MFM Suite and MFM Viewer applications are continually being updated with a focus on usability and providing relevant and updated process information to both control room and field operators, facilitating a joint understanding of the process state.

The project is sponsored by the OECD Halden Reactor Project for the period 2018-2020.

Publications

- Harald P-J Thunem: “Status and Usage of the MFM Suite for Diagnostic and Prognostic Reasoning”, Intl. Workshop on Functional Modelling (IWFM2018), May 24-25, 2018, Kurashiki, Japan

- Harald P-J Thunem: “Current Status of the MFM Suite for Diagnostic and Prognostic Reasoning of Industrial Process Plants”, Proceedings of the ESREL2018 conference (pp. 1011-1016, ISBN 978-0-8153-8682-7), June 17 – 21, 2018, Trondheim, Norway

In addition, see list of related publications under the Diagnostic Decision Support project.

Advanced Control and Automation Support [2009-2014]

- Harald P-J Thunem: “Use-Case of an Agent-Oriented Framework for Supervision, Diagnosis and Prognosis Applications”, Proceedings of the combined ESREL2012/PSAM11 conference (pp. 4910-4917, ISBN 978-1-62276-436-5), June 25-29, 2012, Helsinki, Finland

- Giulio Gola, Morten Lind, Harald P-J Thunem, Atoosa P-J Thunem, Emil Wingstedt, Davide Roverso: “Multilevel Flow Modeling for Nuclear Power Plant Diagnostics”, Proceedings of the European Safety and Reliability (ESREL 2011) conference (pp. 2350-2358, ISBN 978-0-415-68379-1), September 18-22, 2011, Troyes, France

- Harald P-J Thunem, Atoosa P-J Thunem, Morten Lind: “Using an Agent-oriented Framework for Supervision, Diagnosis and Prognosis Applications in Advanced Automation Environments”, Proceedings of the European Safety and Reliability (ESREL 2011) conference (pp. 2368-2375, ISBN 978-0-415-68379-1), September 18-22, 2011, Troyes, France

- Harald P-J Thunem: “ShapeShifter: A Generic Framework for Identifying, Categorizing, Analyzing, Configuring and Managing Information Assets of Systems and Their Agents”, Proceedings of the European Safety and Reliability (ESREL 2010) conference (pp. 390-396, ISBN 978-0-415-60427-7), September 5-9, 2010, Rhodes