Chernobyl NPP decommissioning assistance project

Background

An explosion hit reactor No. 4 at the ChNPP in Ukraine in April 1986. The explosion destroyed the reactor and spread radioactive material into the surroundings. After the disaster, unit 4 could no longer be used and the entire plant including the three other reactors was finally closed in December 2000. The decommissioning of unit No. 1, 2 and 3 is now being prepared whiles the destroyed reactor No. 4 is getting a new sarcophagus.

Decommissioning safely the intact three reactors will be a long-term technological and organisational challenge because of the complexity of the plant, the need for transferring knowledge to the next generations, and the contamination. The overall time schedule for the decommissioning indicates that the final shutdown and preservation will take up to 10 years from now. Then the safe enclosure is set to take 100 years, followed by the final dismantling taking 8-10 years. The state of the final plant site will be a “grey spot”. That is, when all systems are removed from the buildings and the radioactivity of the remaining constructions is lowered to an acceptable free-release level.

When planning, training, and performing the dismantling of a NPP, the need for information about the actual design and the current state of the plant is of highest importance for the staff, the authorities, and the public, in order to perform the work safely, efficiently and with acceptable economically costs. Therefore dismantling a NPP requires highly detailed documentation. Unfortunately a large quantity of the documentation at ChNPP is lost or is in a very bad shape and must be reconstructed, and if documentation exists it may be contaminated. Another problem is the loss of skills among the personnel, because the equipment has not been used for a long time meaning that the personnel is unfamiliar with it or the experienced staff has left the plant. Careful analysing and planning for the dismantling tasks is therefore important in addition to give training to the personnel, both theoretical and in practice.

When planning, training, and performing the dismantling of a NPP, the need for information about the actual design and the current state of the plant is of highest importance for the staff, the authorities, and the public, in order to perform the work safely, efficiently and with acceptable economically costs. Therefore dismantling a NPP requires highly detailed documentation. Unfortunately a large quantity of the documentation at ChNPP is lost or is in a very bad shape and must be reconstructed, and if documentation exists it may be contaminated. Another problem is the loss of skills among the personnel, because the equipment has not been used for a long time meaning that the personnel is unfamiliar with it or the experienced staff has left the plant. Careful analysing and planning for the dismantling tasks is therefore important in addition to give training to the personnel, both theoretical and in practice.

By facilitating improved planning, training and communication, many unwanted incidents might be avoided. Among the planning tools that seek to accomplish this are ALARA (As Low As Reasonably Achievable) support tools. Virtual reality based ALARA tools have the potential to being useful for minimizing doses but also for improving communication between involved parties, and thus safety.

The Chernobyl Decommissioning Visualisation Centre

In 2006, the Norwegian authorities decided to fund a project at ChNPP establishing the Chernobyl Decommissioning Visualisation Centre (CDVC) using VR technology in the decommissioning of the three intact units.

A first version of CDVC was established in 2007 with visualisation of a 3D virtual environment, features for dismantling procedure development and documentation, in addition to basic features for radiation visualisation. The CDVC at that time was a pilot version. The software developed supported only the most basic functionality for making dismantling procedures.

In April 2008, the Norwegian government approved its action plan for nuclear activities, which defines how Norway through assistance projects will contribute to increased safety at nuclear power plants and nuclear installations in Russia and in the former Eastern Europe. In the spring 2013 the plan was updated and extended until 2017. The action plan says that the decommissioning of ChNPP should be looked on as a unique knowledge base for decommissioning planning.

The CDVC project had slow progress in 2011-14 due to the need for establishing an intergovernmental agreement on cooperation between Norway and Ukraine regarding the Norwegian funded assistance projects in Ukraine. The agreement was needed in the CDVC project before the requested, formal registration of the project in Ukraine could be fulfilled. On 30th November 2012 the intergovernmental agreement was signed in Oslo. The agreement lays the formal foundation for the practical execution of Norwegian assistance projects in Ukraine taking place at nuclear plants with special focus on ChNPP in addition to other on-going work concerning nuclear safety and radiation protection in Ukraine.

The CDVC was finally established in February 2016 with the purpose of introducing new VR and 3D modelling technologies to ChNPP. It is expected to be an important tool for ChNPP in optimising the decommissioning plans and in the organisation of the work tasks. This includes the development of dismantling procedures and in radioactive waste management using visualisation to improve efficiency and safety of work performance at the ChNPP decommissioning stages, in particular:

- For use during planning of decommissioning activities;

- For effective storage and presentation of information about the ChNPP facilities designed for works at the subsequent and final stages of decommissioning.

- During periodical comprehensive engineering and radiations surveys;

- During dismantling activities;

- During radioactive material management;

- For personnel training;

- For presentation of information to the public, authorities and licensing bodies;

The CDVC enables the ChNPP staff to plan procedures for various work tasks involved in dismantling the facility with special focus on the tasks in the radioactive parts of the plant. The CDVC visualises the gamma-radiation fields in an area based on measured data and makes occupational dose calculation for estimating the dose to be received by personnel when entering the real, radioactively contaminated area. The visualisation of radiation and the dose calculation may help minimise the personal risks and optimise the usage of personnel. The CDVC technology is also a valuable tool to support the making of the needed documentation and for training the dismantling phase. Thereby CDVC supports ChNPP in preserving the decommissioning expertise and knowledge at the plant in a long term perspective. The CDVC can be a pedagogical means for the ChNPP personnel in training the dismantling procedures. Intensive training before the real dismantling process may be effective for reducing radiation exposure dose, workload and for enhancing safety. In addition, the CDVC provides the decommissioning project team with an effective medium in presentations to the public as well as for communicating with the management and the licensing authorities.

CDVC software developed by IFE

The CDVC consists of the following software developed by the IFE: ChNPP ProCre, ChNPP Planner and ChNPP PCT.

ChNPP ProCre for dismantling procedures planning

ChNPP ProCre makes it possible for a group of engineers and other specialists to test out plans and procedures for various work tasks involved in dismantling a nuclear facility. That is to develop dismantling procedures by deciding the order in which items are going to be removed and to document the procedures. The scenario made in ProCre can be used as basis for planning the use of the people in the radioactive environment to be done in the next CDVC software; ChNPP Planner.

ChNPP Planner for planning personnel usage

ChNPP Planner lets one visualise gamma-radiation fields in the simulated area based on measured data or data obtained as part of comprehensive engineering and radiation survey (CERS) and to do occupational dose calculation for estimating the dose to be received by personnel when entering the radioactively contaminated area. The visualisation of gamma-radiation fields and the dose calculation can help to minimise the personal risks and to optimise the usage of personnel.

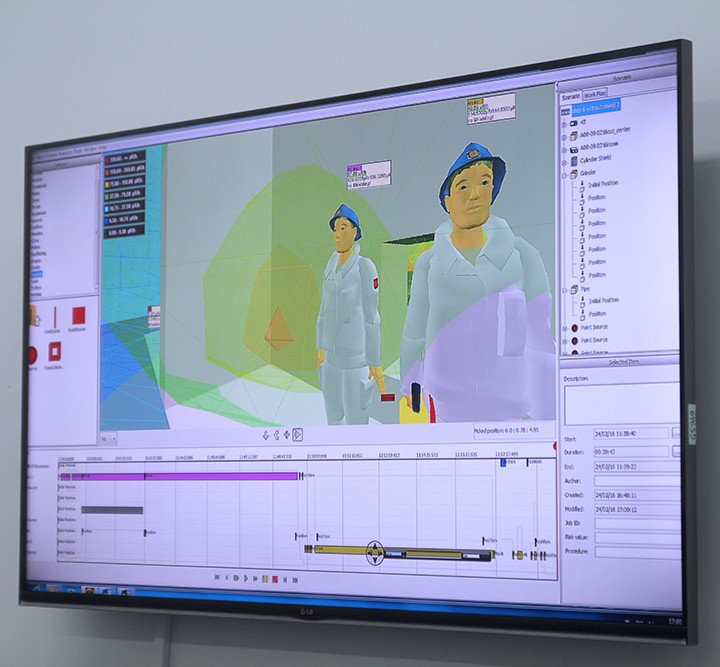

The ChNPP Planner allows the users plan the work by simulating tasks in a VR model of the work environment and by using manikins to represent workers. The ChNPP Planner then calculates in real-time the radiation exposure for the given scenario. The user can view dose distribution graphs to determine if the doses are within acceptable limits, and to identify when and where high radiation doses were incurred. The ChNPP Planner thereby supports the principle about “as low as (is) reasonably achievable” (ALARA).

The ChNPP Planner was first based on the Halden Planner developed in the OECD Halden Reactor Project. Today’s ChNPP Planner is a version of IFE’s VRdose adapted for ChNPP’s special needs.

ChNPP Procedure Creator and Trainer for procedure training

ChNPP Procedure Creator and Trainer (ChNPP PCT) can be used for training personnel doing work tasks before actually doing the tasks in real life. One or more trainees can do collaborative training on a predefined work procedure in a VR environment (VE).

Each trainee is represented by a manikin in the VE. The trainees can see each other and communicate in the VE. That makes it possible to train on procedures involving real-time cooperation between the trainees when doing a task.

The trainee is able to go through a predefined work procedure. That is to select objects in the VE, move and manipulate objects in a realistic manner in addition to performing other physical work tasks. The trainee may get detailed technical data about the physical objects. Different levels of guiding are available; from free exploration in the VE to full guiding and presentation of the correct procedure.

Support for training on radiation situations is implemented making it possible for the trainee to always see the actual gamma-radiation fields in the form of a field distribution map. Also the trainee can be informed about the dose rate calculated when finishing dismantling activities in the virtual environment. In addition, the trainee can be informed about other physical risks, both visible and non-visible ones, which may result in personnel injury, damage to the equipment or to the environment.

The instructor has tools for setting up the training scenarios for each individual trainee including managing the incidents that the trainee may experience. The instructor is able to log the trainee’s actions during the training and evaluate the trainee’s performance.

Additional CDVC software and equipment

The final version of the CDVC consists of the three software applications: ChNPP ProCre, ChNPP Planner and ChNPP PCT. In addition the CDVC includes hardware and software needed for the ChNPP staff for data collection, modelling of ChNPP facilities and development of scenarios to be visualised with the software from the IFE.

More information

VRdose (IFE’s commercial software for decommissioning planning)

Chernobyl Decommissioning Visualisation Centre (CDVC):

https://www.youtube.com/watch?v=txnoidoZzEk&feature=share