We are glad to announce that a large part of the anorthosite processing has been already optimized by IFE. Improved anorthosite dissolution step (leaching step) at optimal process conditions for silica quality control, the silica separation and purification step and a new configuration for the alumina production step have been successfully developed.

As a result, two of the three co-products expected from anorthosite have been studied and optimized towards industrial specifications at laboratory scale. We have gained valuable knowledge about the properties control, to be able to adjust the process conditions towards various product qualities and yields. Currently, these results are being further assessed under commercial standards by our industrial partners, to examine the quality and determine their potential market value.

Furthermore, IFE´s data and know-how has been transferred to Herøya Industrial Park for upscaling the leaching step and silica separation to TRL 5 (Technology Readiness Level). The campaign in their 150 l reactor is planned within Q2-Q3 2022. The different silicas and the resulting liquid fraction will be then evaluated to validate IFE´s findings at laboratory scale.

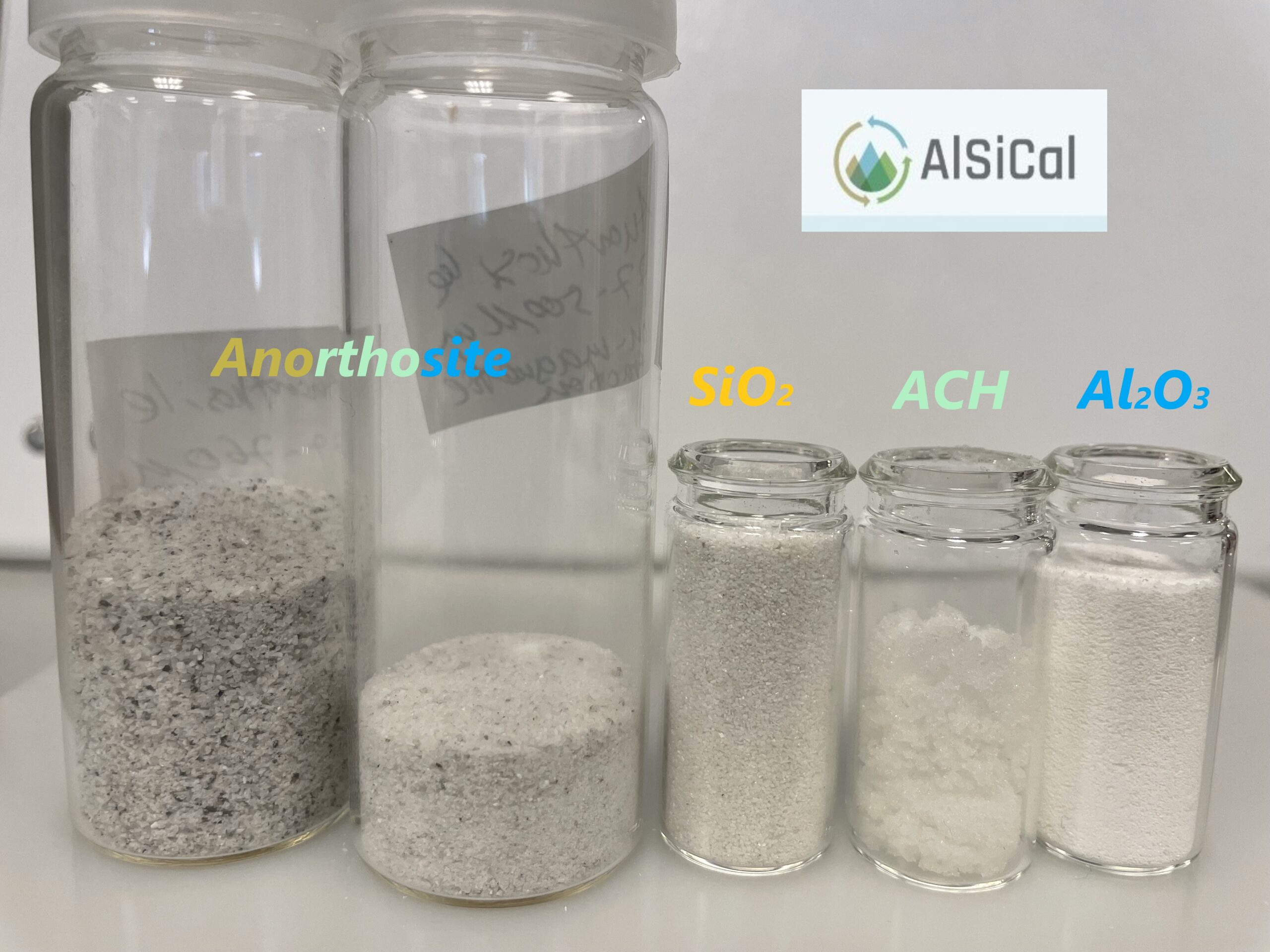

From left to right, respectively: Anorthosite, magnetically separated non-magnetic fraction of anorthosite, silica product, ACH (Aluminium Chloride Hexahydrate) intermediate product and alumina.

In parallel, all process information from IFE is continuously being transferred to the modelling partners (INPT and UNIZAR) for reactors and process modelling, which set the basis for the final techno-economic, LCA and business assessments later in the project.

The achieved results are very satisfactory, though there is still ongoing one additional product optimization, work ahead and challenges to solve in the AlSiCal project. The overall goal is to propose the most competitive and environmentally friendly process for anorthosite into valuable products. The whole Consortium keeps high pace and high motivation to continue innovating and creating maximum value out of this innovative project. And we are positive that we will reach new important milestones in the coming months to progress further beyond state-of-the art-knowledge.