(Illustration: HZDR, Tino Gottschall)

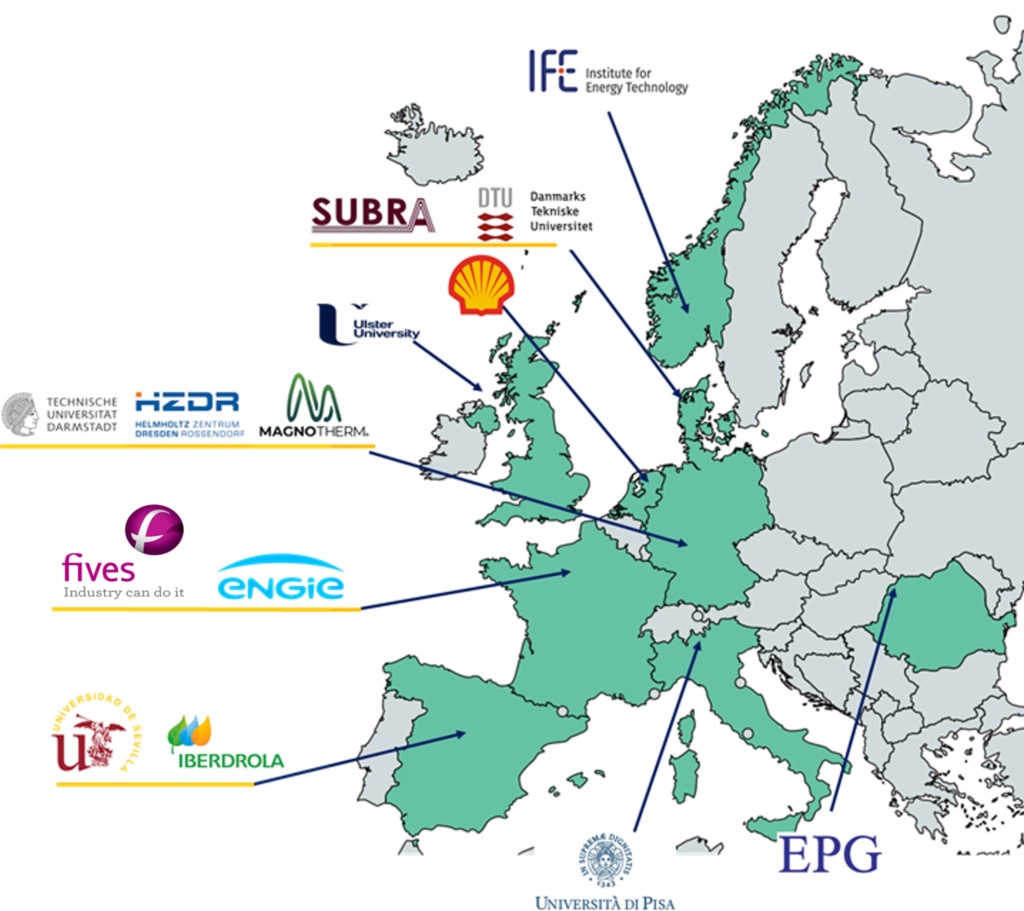

The HyLICAL project (Development and validation of a new magnetocaloric high-performance hydrogen liquefier prototype) will run from 2023 to 2027. The project is coordinated by the Norwegian Institute for Energy Technology (IFE), and is supported by the Clean Hydrogen Partnership and its members.

The intended technology development will result in a substantial reduction in energy consumption, capital investment, and operating cost for hydrogen liquefaction, in addition to a safer and more sustainable storage of liquid hydrogen. The project will contribute to the green transition of industry and increase the potential to optimize utilization of renewable energy sources (RES) in off-grid configurations.

This will be obtained from research and innovation on materials, design, simulation, construction, and testing of a liquefier in addition to work on safety, regulations, and roadmaps relevant for this technology. Thus, the enhanced research capacity developed by HyLICAL will benefit the scientific community, industry, policymakers, climate, and society.

Liquefaction of hydrogen, as to be demonstrated in HyLICAL, will allow handling of the large volumes of hydrogen, and will contribute to speed up the decarbonization and the development of a sustainable society. Liquid hydrogen (LH2) has 70% higher volumetric energy density than compressed hydrogen at 700 bar. This makes it attractive to transport LH2 and to store it in massive quantities, enabling transport of hydrogen by road/ship from centralized/decentralized production plants to customers, or use of LH2 as an energy carrier in heavy duty mobility.

Potential impact of the technology development:

- Up to 50% reduction in energy consumption during liquefaction compared to conventional technology

- Significant reduction in CAPEX and OPEX for liquefaction

- Possibility of liquefying hydrogen in far smaller volumes than with current technology

- Reduced boiling of hydrogen during storage

- Eliminate the use of compressors which reduce moving parts (reduced maintenance) and reduced noise

- Reduced use of critical raw materials

- Safer storage and transport of liquid hydrogen

- More volume-efficient storage of liquid hydrogen

- More sustainable transport and storage of liquid hydrogen

- Increase the opportunities to utilize trapped power and power from RES

- Increase the opportunity for sustainable local communities

- Increased knowledge of magnetocaloric materials

- Increase the profitability of Norwegian hydrogen exports

- More energy-efficient liquefaction and the possibility of having small-scale liquefaction plants will help to accelerate decarbonization and the development of a sustainable society.

Potential to meet societal and industrial challenges

The HyLICAL project impacts society in several ways. The possibility to implement small-scale hydrogen liquefaction from RES opens for a more distributed hydrogen economy, than today’s technology that is suitable only for large volumes. As such, it can contribute to sustainability and growth in smaller communities by integrating e.g., locally generated wind, solar, or hydroelectric power into the production chain (cf. also section below).

Furthermore, the improved efficiency promised by the HyLICAL technology can be critical to lower the LH2 production cost sufficiently to make LH2 the preferred choice of energy carrier in many areas of society, including the transport sector (marine and onshore), thus helping to achieve a less polluted environment with obvious health benefits.

The major industrial challenge as of today is the high liquefication cost and the CAPEX needed to make conventional liquefaction plants profitable due to the economy of scale. If the technology developed through HyLICAL succeeds in cutting the liquefication cost in half, even small-to-medium sized liquefaction plants may become profitable thus allowing local hydrogen producers and end users to benefit from this technology.

Promotion of future value creation in industry and civil society

According to the Global Hydrogen Review 2021 published by The International Energy Agency (IEA), hydrogen is increasingly important to achieve net zero emissions by 2050. A sturdy growth in the hydrogen demand and the adoption of cleaner technologies for its production thus enable hydrogen and hydrogen-based fuels to eliminate up to 60 Gt CO2 emissions in the period 2021-2050, representing 6% of total cumulative emission reductions.

In a carbon-neutral society, hydrogen is produced from RES such as solar and wind power. Hydrogen can be stored and transported as compressed, liquefied, or as solid or liquid hydrogen carriers.

This project will contribute to value creation in several ways:

- (i) Increase the potential and the outcome of hydrogen export;

- (ii) Increase the potential for locally produced (small-scale possibilities) hydrogen for industry, transport, and balancing of energy systems which again leads to more sustainable and competitive industry and mobility;

- (iii) Increase the potential of zero emission alternatives for transport that cannot be met by other sources (batteries, fuel cells, electricity).

- (iv) Increase the possibility to use hydrogen to reduce the long-term peak demand on the electrical grid.

Availability of sustainable H2 – in particular, in its highest volumetric energy-density form, LH2, as an energy carrier and as a raw material for industrial processes, will give the industry the possibility to utilize H2 as a CO2-free energy source or raw material in production processes.

LH2 may also be used in long distance and local transportation (ships, buses, and trucks) as well as for storage of locally produced wind or solar energy. Since the proposed technology can be used for smaller-to-medium scale production, in addition to large scale, LH2 can then be produced, stored, and utilized locally.

In addition, bridging the technology gap from gas storage to liquid storage, will create possibilities for industry to deliver complete systems for small-to-medium scale LH2-production to the world market.

HyLICAL specifically addresses stated policy goals.

Related news

-

29. January 2025

New Discovery in the Arctic Ocean: Borealis Mud Volcano

The Borealis Mud Volcano, a recently discovered underwater structure in the Barents Sea,…

-

19. September 2022

Speeding up the green transition

IFE and Nel have received 13 million NOK from The Research Council of Norway to accelerate…