“Does anyone here know anything about mathematical modelling of physical phenomena in petroleum well technology?”

In 2016, during a university course at Kjeller, such a question was asked by a participant from the startup company Oliasoft. Founded by entrepreneurs with ambitions to digitalize and improve design processes for oil wells, Oliasoft was looking for cutting edge expertise in mathematical modelling of physical phenomena in well technology. The lecturer, an employee at the Institute for Energy Technology (IFE), knew exactly where to look: the Department of Flow Technology.

For decades, this department had developed advanced simulation tools for industry. A first meeting was arranged in 2017 –five senior scientists hunched together over a small laptop.

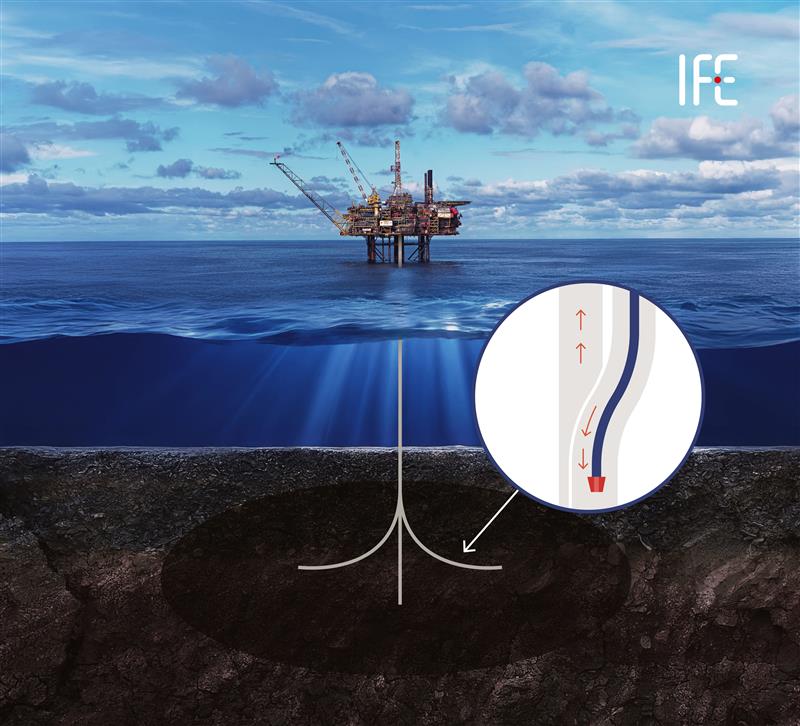

Despite the modest setup, it quickly became clear during that first meeting that Oliasoft had found a valuable partner. IFE presented a concept for a new calculation tool capable of simulating temperature profile in wells – whether for petroleum, carbon storage, or geothermal energy.

What, why and value?

The collaboration evolved rapidly. Oliasoft continued to develop its business model and integrated more and more functionality into its software. IFE, for its part, contributed deep scientific expertise and developed, among other things, a proprietary module for PVT calculations – a method for determining the composition of oil components as a function of pressure, temperature, and volume. This module was self-financed by IFE, allowing the institute to retain ownership of the technology.

Fast forward to today, and that concept has evolved into Oliasoft WellDesign – a cutting-edge, cloud-based well engineering platform that replaces outdated spreadsheets and legacy tools with fast, physics-based calculations for oil, CCS, and geothermal wells. This is not just software; it’s a complete transformation of how the industry approaches well planning.

Traditionally, well planning has been slow, manual, and error-prone, relying on fragmented tools and spreadsheets. Oliasoft WellDesign automates complex thermal and fluid simulations, cutting weeks off design time and enabling real-time scenario analysis. It also reduces costs for software licenses in a market previously dominated by near-monopolies.

The significance of this innovation was underscored in August 2025 when Equinor gave full approval for Oliasoft WellDesign across its entire organization. This endorsement from one of the world’s largest energy companies signals that the platform is now a standard for well design – and a key enabler of the green shift.

The numbers speak for themselves: Equinor alone plans hundreds of wells annually, each costing $50–150 million USD. Even small-time savings translate into hundreds of millions in cost reductions. Add to that recurring licensing revenue for IFE and Oliasoft, and the emergence of a new Norwegian tech champion becomes clear.

From Concept to Solution

The innovation journey was not only technical – it required patience, trust and perseverance. All software intended for use in the oil industry must undergo extensive qualification and testing. That’s why the joy was immense when Equinor, in August 2025, officially approved the software for use across its entire organization. This was not only a victory for Oliasoft and IFE, but also proof of how the research institute sector can contribute to real value creation in industry.

This milestone marked far more than a product qualification. It was a resounding endorsement from one of the world’s most respected energy companies: a recognition that the technology developed by IFE and Oliasoft meets the highest industrial standards and delivers real value.

For IFE and Oliasoft, Equinor’s acceptance represents a leap from idea to large-scale implementation. For Norway, it highlights how close collaboration between research and industry can transform scientific insight into world-class innovation.

The Invisible Power of the Research Institute Sector

The story of IFE and Oliasoft illustrates how the research institute sector acts as a catalyst for innovation – often behind the scenes. When industry partners fund technology development, they typically own all intellectual property (IPR), while institutes like IFE contribute with expertise, design, and scientific insight. The role of the research institute sector is to offer extreme competence – specialized knowledge that turns ambitious ideas into proven, scalable technologies. Innovations like these can solve complex challenges and accelerate the development of new solutions.

“Fly Me to the Moon”

The film Space Cowboys ends with Frank Sinatra’s song “Fly Me to the Moon”, as the camera zooms in on the surface of the Moon, showing that Hawk not only landed there before he died, but also survived long enough to lie against a rock formation and look back at Earth.

No one died during this innovation journey, but as an internal joke, the IFE team was nicknamed the “Space Cowboys,” referencing the 2000 film where four aging astronauts are sent into space to save the day.

Just like in the movie, the IFE team delivered – demonstrating that experience, expertise, and collaboration can create solutions that truly make a difference. And with Equinor now embracing the technology, this story shows that even the boldest ideas can reach the stars. Are you next?

Related news

-

20. December 2023

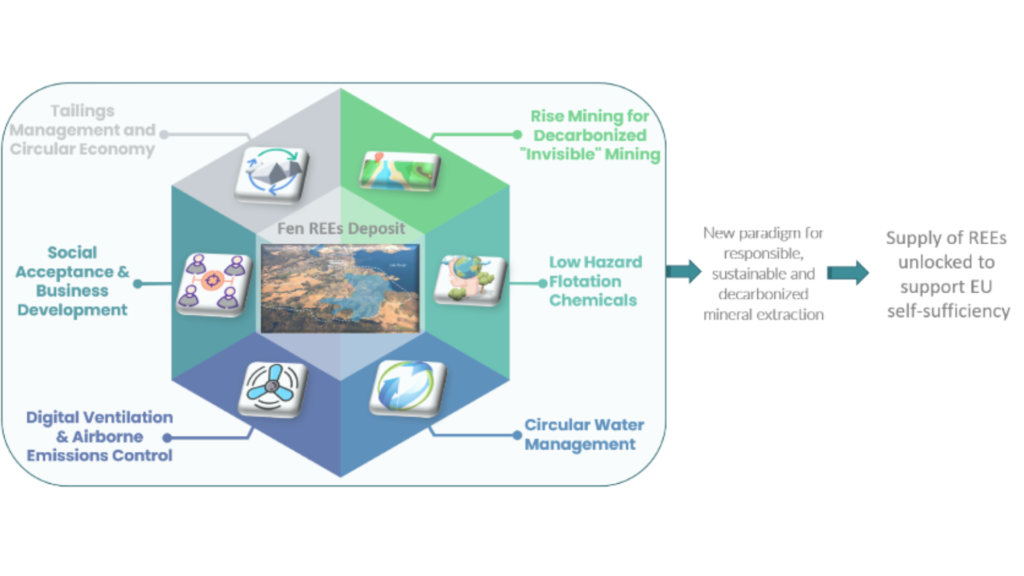

Horizon Europe Project REESOURCE launches in Norway to unlock Europe’s Rare Earth Element Supply

The Horizon Europe Project "REESOURCE," a groundbreaking initiative aimed at…

-

19. September 2022

Speeding up the green transition

IFE and Nel have received 13 million NOK from The Research Council of Norway to accelerate…