Water Electrolysis

IFE’s Hydrogen Technology Department has decades of experience in testing and validation of low-temperature water electrolysis technologies. At IFE Hynor we provide the capability to test cutting edge PEM, alkaline and AEM components, as well as validating the performance and durability of established technologies.

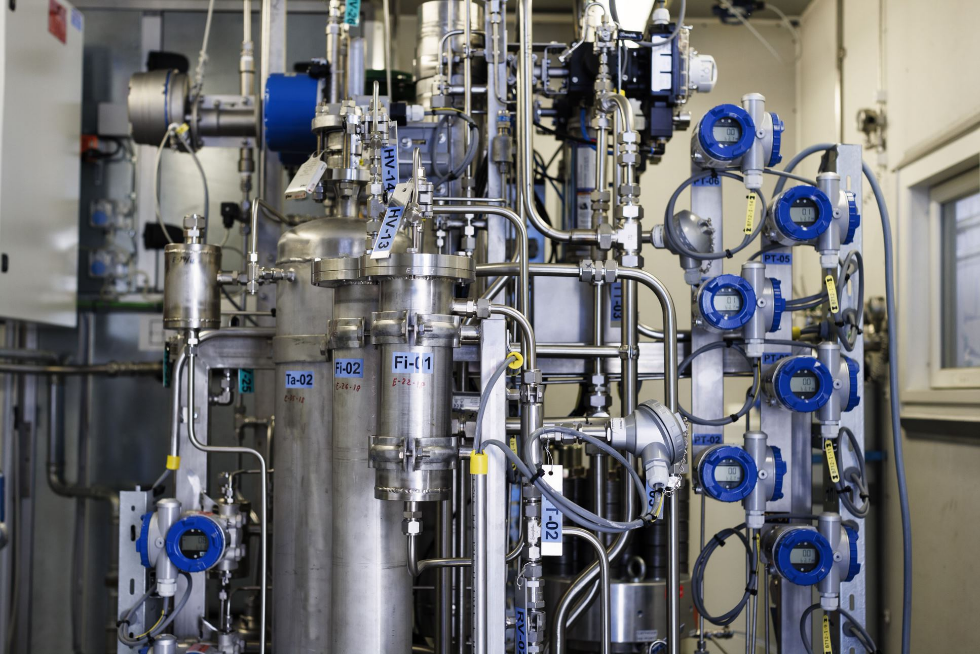

The following electrolyser testing infrastructure is available:

- High-pressure PEM water electrolysis test rig – built in-house

- Rated capacities: 410 A / 150 V (max 33 kW) / 200 bar

- Ideal for

- Testing and qualification of stacks and key system components

- Validation of advanced control strategies and hybridization with Li-ion batteries

- Parameterization of dynamic system models

- PEM water electrolysis test station – Greenlight E60

- Rated capacities: 20 V / 250 A / 30 bar (max 3 kW)

- Ideal for

- Testing PEM electrolysers from 25 – 50 cm2 under a full range of operating conditions

- Characterising new electrolyser materials and components

- Long term and accelerated stress testing of components (fully automated testing)

- AEM/Alkaline testbench

- Rated capacities:

- Ideal for investigating single cell (up to 25 cm2) performance and durability under different operational conditions (such as temperature, KOH molarity, different impurities etc.)

IFE’s Corrosion technology department provides R&D services on materials and corrosion for the energy industry, including hydrogen, oil and gas, CCS and geothermal energy production. We perform corrosion and cracking testing of material candidates for critical stack and balance of plant components for alkaline water electrolyzers as part of industry-funded projects, as well as damage analysis, surface characterization and multiphysics modelling of electrolyzer operating conditions.

The Corrosion tech dept has about 500 m2 of HTHP laboratories with zones for toxic gas and Ex testing. IFE’s line of corrosion test equipment consists of autoclaves and flow loops for HTHP testing, and glass cells for testing at ambient pressure. Most of the autoclaves and loops are made of nickel-based alloys such as Hastelloy C-276, which makes them suitable for testing with alkaline environments.

Water Electrolysis Research Capabilities

- PEM water electrolyzer stack testing up to 410 A, 33 kW and 200 bar

- Electrochemical in-situ characterization (EIS), including advanced impedance spectroscopy

- Design and operation of advanced PEMWE system configurations

- Long-term durability measurements including dynamic load profiles

- Test protocol development ex. accelerated test protocols and condition monitoring techniques

- Modeling of dynamic operation of PEMWE-systems (e.g., renewable energy-based systems)

- Experimental studies of materials corrosion and cracking mechanisms in alkaline electrolyzers

- Water electrolysis system design and techno economic analysis

- Testing and analysis of corrosion, cracking and other degradation of materials for critical stack and balance of plant components in alkaline electrolyzers.

Projects:

REHSYS – Renewable Energy Hydrogen Systems based on PV, Wind, and Water Electrolysis – IFE

H2ACCELERATE – Fast-tracking advanced PEM electrolysis materials and monitoring – IFE

H2MARITIME – Hydrogen and Fuel Cells for Maritime Applications

FME HYDROGENi – Norwegian research and innovation centre for hydrogen and ammonia – IFE

High-pressure PEM water electrolyser performance up to 180 bar differential pressure – ScienceDirect

More information:

High-Pressure PEM Water Electrolysis System – Zenodo