New project “Hybrid nanophotochromic oxidized yttrium hydride films” awarded through FRINATEK program

Heat gains or losses through windows in residential buildings are responsible for 25-30% energy uses due to cooling and heating. Multiple strategies are explored by R&D organizations worldwide to minimize the energy consumption caused by air leaks, poor thermal insulation and radiative losses through windows.

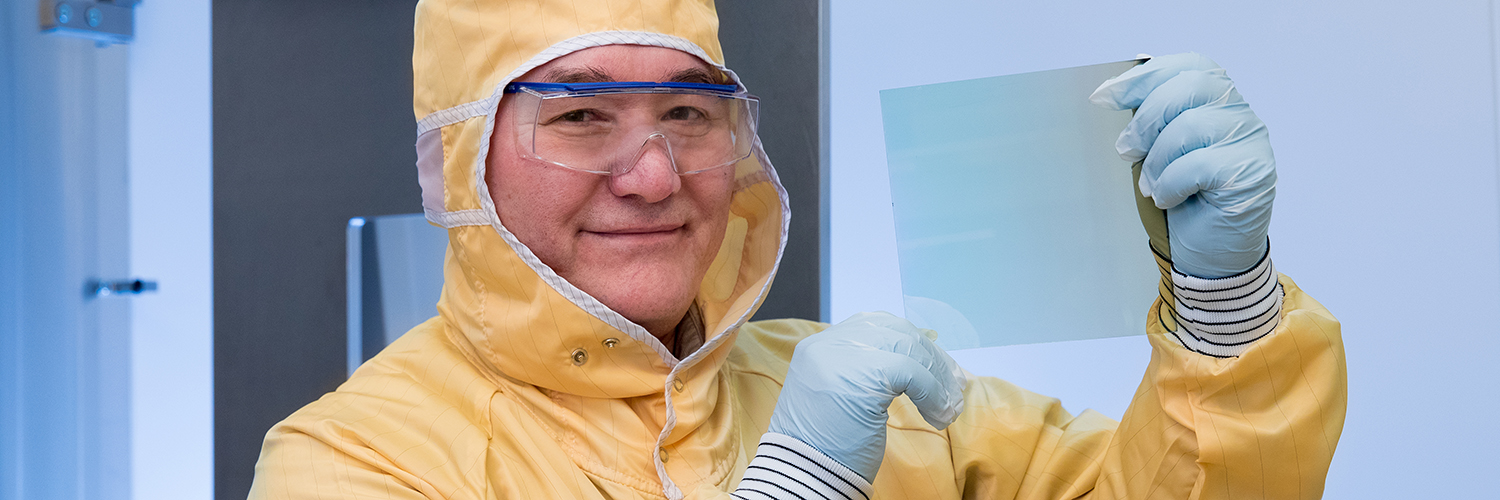

Institute for Energy Technology (IFE), in collaboration with the University of Uppsala (UU) and Istanbul Technical University (ITU), intends to develop a technology known as photochromic windows by using hybrid materials based on yttrium.

The project utilizes IFE’s expertise in chemistry of hydride materials combined with the advanced characterization facilities available at UU and ITU. Such characterization is necessary for fundamental understanding of this complex material. IFE aims to develop not only the nanomaterials and explore the routes of their preparation, but also plans to synthesize and study of properties of their composites with various polymers. Such approach will allow to fabricate flexible photochromic films with possibility to retrofit the technology to the currently existing window solutions.

Photochromic materials

The studies of yttrium hydride as a material for hydrogen storage conducted at IFE over the last several years led to the discovery of photochromic effect observed in hydride materials after exposure them to air. That made yttrium oxyhydride, formed during such exposure, a material of choice for the present project. It belongs to emerging class of oxyhydride materials where oxide and hydride anions share the same sites in the crystal lattice. The effect of photochromism generally refers to reversible change of materials color when exposed to sunlight. While the nature of the effect in oxyhydride materials is still fundamentally unclear, they have already showed a great potential for light-induced change of their transmittance from 90 to 50 %. However, commercialization of the technology in its present stage is limited due to ceramic nature of yttrium oxyhydride, dependence of photochromic effect on angle of incidence of sunlight, possibility of the film degradation, and poor material adhesion to the transparent substrates. In addition, the preparation of the initial hydride materials requires a complicated deposition process.

Materials challenges

Despite the promising properties of the material there are still many problems to solve, which will be performed within the present project. One of the fundamental problems associated with the use of yttrium oxyhydride materials is the oxidation step necessary to convert the metallic hydride into non-stoichiometric oxyhydride, which acts as the photochromic active material.

- Understanding the oxidation process is necessary for controlled preparation of the materials, – says Dr. Smagul Karazhanov, manager of the project.

The team at IFE plans to explore the parameter space to find the best performing material which also will survive the harsh environment when used in the window coatings.

Technology potential

The project aims to synthesize a composite material, where the optically active oxyhydride will be embedded in the polymer matrix, which will allow easy further processing. Moreover, such approach will allow to retrofit the photochromic films into the existing window technologies.

- Finding proper polymer matrix material, which will provide stability and proper optical properties will be the major challenge in the project, – says Dr. Alexey Y. Koposov, key scientific personal in the project and former senior scientist at SHARP Corporation.

The technology utilizing the present scope of materials has already attracted attention of the industry, which also resulted in establishing a spin-off company Sunphade AS. Concidering the limited availability of photochromic devices in the market, the possibility to contribute with new material solutions at reduced cost, as proposed in the present project, is of high interest for the European industries and will improve competitiveness and strengthened European industrial leadership in this sector. The project, funded by Norwegian Research Counsel, will start in the first quarter of 2019 and is expected to continue through 2022.

For additional information, please contact:

Dr. Smagul Karazhanov, Project Manager, +47 451 63 599 / Smagul.Karazhanov @ife.no

Alexey Koposov, Senior scientist, +47 966 94 531 / Alexey.Koposov@ife.no