BTSC

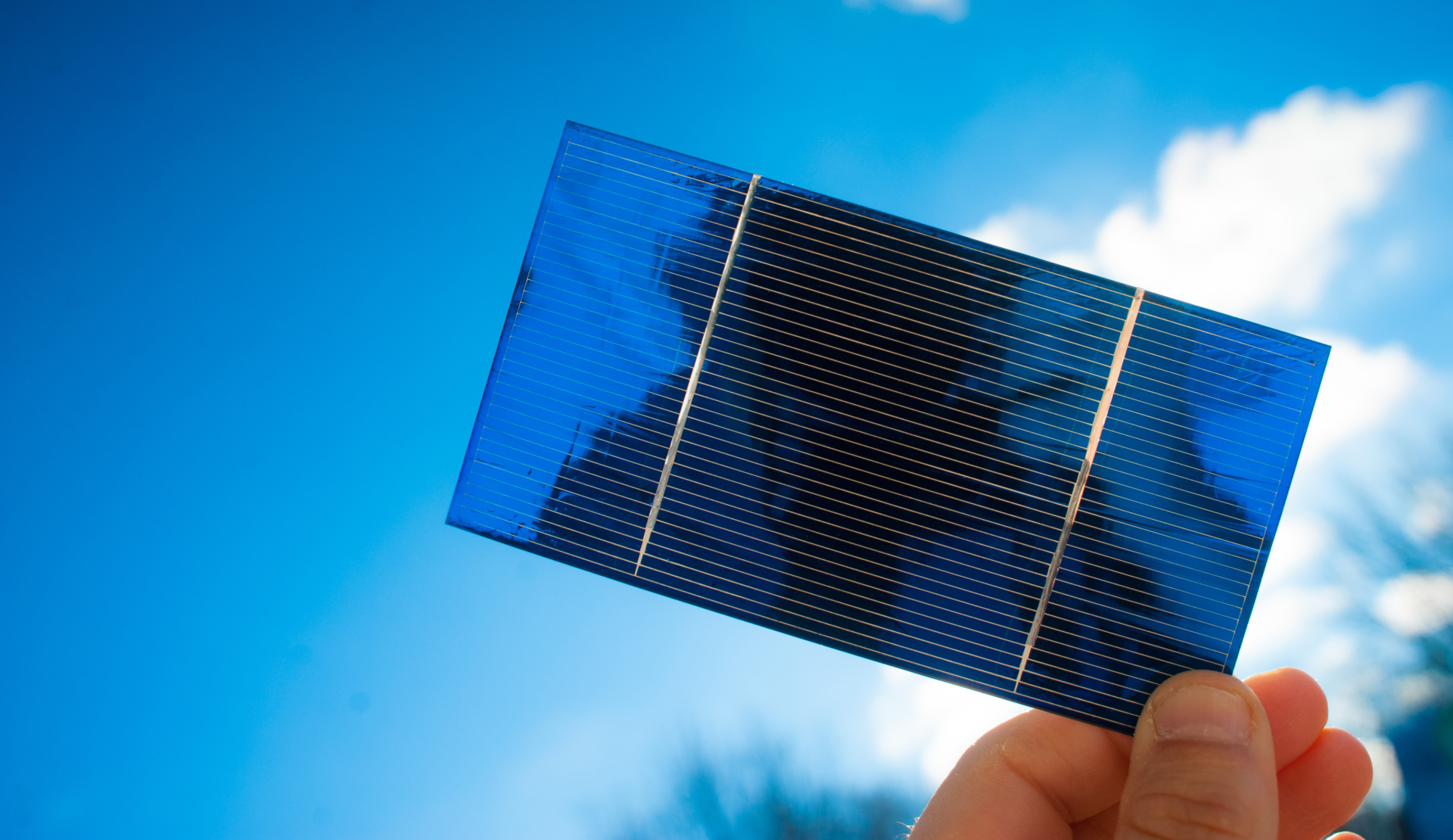

Photovoltaic (PV) solar energy conversion is considered a key renewable energy source for the future. Currently, the solar cell market leader is wafer-based crystalline Si (95 %), whereas thin film (TF) solar cells accounts for approximately 5 %.

Unique capabilities of the bifacial solar cells

While most solar cells on today’s market are produced as single‐sided or monofacial, the BTSC-project focuses on semi‐transparent bifacial solar cells. Where the monofacial solar cells can collect photons only from the side that faces the sun, and thus, have limited applications, the semi‐transparent bifacial solar cells operate efficiently in full and faint sunlight, as well as snowy conditions. Snow in winter, below or behind bifacial modules, produces an albedo (whiteness) value close to unity, increasing light reflectance to the rear side of the module. As a result, power generated due to illumination of the rear side of the module can approach that of the front side at high albedo values. The market potential of these solar cells for residential and commercial solar PV in Nordic and Baltic countries is tremendous and present unlimited potential applications ‐ from light harvesting in shaded parts of houses to windows of electric cars to architecture.

The goal of the project is to enhance research‐based knowledge development in Baltic‐Nordic states through cooperation by developing materials for semi‐transparent bifacial cost‐effective solar cells. These solar cells present unlimited potential market applications ‐ from light harvesting in shaded parts of houses to windows of electric cars to architecture.

The market potential of these solar cells for residential and commercial solar PV in Nordic and Baltc countries is tremendous.

The intention is to develop modules from semitransparent bifacial thin film solar cells based on Sb2Se3 [Antimony selenide]. SOL brings its expertise in theoretical modelling of materials and defect chemistry by first-principles calculations and in study of solar cell performance by device modelling.

Materials challenges

The project builds on the pre‐existing complementary scientific expertise in the related fields of synthesis of novel organic and inorganic hole conductor materials (KTU), their characterization (ISSP UL), thin film deposition and solar cell fabrication (TalTech), materials modelling and defect chemistry by first principles calculations as well as device modelling for solar cell modelling (IFE).

The major challenge to be addressed will include

1) finding a defect forming shallow level in the band gap, with possibility of doping in large concentration

2) establishing the low-cost method of creation of such defects

3) designing and fabricating high efficiency bifacial Sb2Se3-solar cells.

Who and when

The BTSC project will start in the first quarter of 2021 and is expected to continue through 2023.

The research group consists of The Solar Energy Department (SOL) at IFE in collaboration with the Kaunas University of Technology (KTU), Kaunas, Lithuania, Tallinn University of Technology (TalTech), Tallinn, Estonia, Institute of Solid State Physics (CFI) of University of Latvia, Riga, Latvia.

For additional information, please contact:

Dr. Smagul Karazhanov, project manager at SOL, +47 451 63 599 / Smagul.Karazhanov @ife.no