Lillestrøm, Norway – January 27, 2025

The REMEDHYS project, a bold initiative to reshape hydrogen storage technology, officially begins on 22 January 2025 in Norway. This innovative project will develop solid-state hydrogen storage solutions using metal hydrides, providing a compact, safe, and sustainable alternative to traditional compressed and liquid hydrogen methods.

Project Overview:

- Project title and Acronym: Recycled Metals for Aboveground Hydrogen Storage (REMEDHYS)

- Project period: 2025-2028

REMEDHYS Concept

REMEDHYS (Recycled Metals for Aboveground Hydrogen Storage) focuses on solid-state hydrogen storage using metal hydrides (MHs). This technology chemically binds hydrogen to metals, enabling storage of hydrogen at low pressure (<50 bar) and ambient temperature, ensuring enhanced safety while minimizing infrastructure requirements. By using recycled metals sourced within Europe, REMEDHYS also supports the EU’s push for circular economy practices and reduced reliance on imported raw materials.

“REMEDHYS is an exciting step forward in sustainable hydrogen storage. We’re bringing innovative technology to the market while aligning with Europe’s climate goals,” says Stefano Deledda, Project Coordinator.

Compared to traditional compressed or liquefied hydrogen storage, the MH approach offers significant advantages:

- Enhanced safety by reducing risks of sudden hydrogen release.

- Improved efficiency through integration with waste heat sources.

- Smaller footprint with reduced safety distances and infrastructure requirements.

The use of recycled starting materials for the production of the hydrogen storing alloys is expected to significantly reduce the investments costs of hydrogen storage units based on MHs, making them competitive with compressed and liquid hydrogen storage technologies.

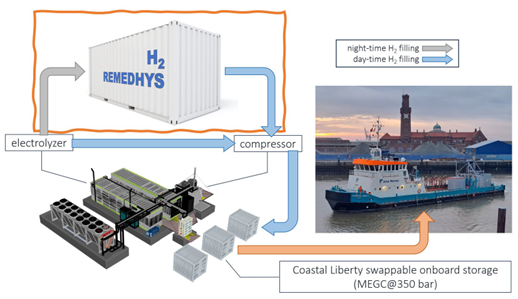

Figure 1. REMEDHYS concept

Real-World Impact and Applications

The project aims to demonstrate the feasibility of large-scale aboveground hydrogen storage for diverse markets, including transportation and industrial applications. By showcasing its modular and scalable technology, REMEDHYS will support Europe’s transition to renewable energy while reducing reliance on imported raw materials.

Real-World Validation in Cuxhaven, Germany

The project’s modular hydrogen storage system, with a capacity of 100 kg and a density of 40 kgH₂/m³, will be validated at an operational hydrogen production site in Cuxhaven. It will be integrated with a 2 MW PEM electrolyzer, supplying hydrogen to the Coastal Liberty, an offshore service vessel. This large-scale demonstration will establish the system’s viability for broader applications, including ports, heavy transport, and industrial use.

Collaboration and Expertise

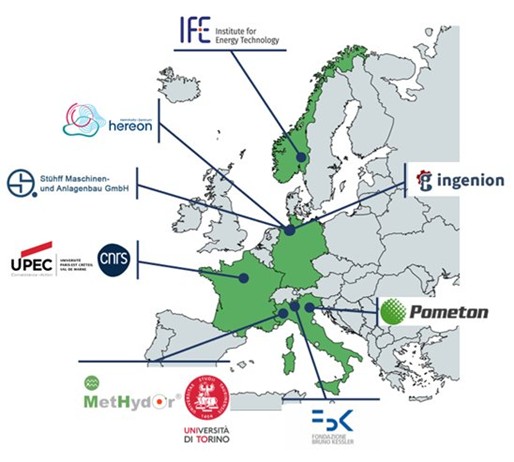

REMEDHYS is a collaboration of top-tier European research institutions and industry leaders. The consortium includes four research centers (IFE, HEREON, CNRS, FBK), two universities (UNITO, UPEC), and four industrial partners (POMETON, SMAB, METHYDOR, INGENION). Together, they bring expertise in chemistry, engineering, and energy systems to deliver innovative solutions for hydrogen storage.

REMEDHYS Partners:

- Institutt for Energiteknikk

- Università degli Studi di Torino

- Helmholtz-Zentrum hereon GmbH

- Pometon SpA

- Stühff Maschinen- und Anlagenbau GmbH

- CNRS – Institut de Chimie et des Matériaux Paris Est

- Fondazione Bruno Kessler

- Ingenion Hydrogen GmbH

- MetHydor srl

- Université de Paris-Est Créteil

REMEDHYS Project has received funding from the European Union Horizon Europe Research and Innovation program under grant agreement No. 101192503. The project is supported by the Clean Hydrogen Partnership and its members.

For more information, contact project Coordinator Stefano Deledda: stefano.deledda@ife.no

Related news

-

5. January 2026

From Idea to Industry: The Innovation Journey of IFE and Oliasoft

In the world of innovation, the most significant changes often begin with a simple…

-

25. November 2025

The WellFate Project Releases New Video on the Challenges of Old Offshore Wells

The Reservoir Department at IFE has published a new video that highlights an important…