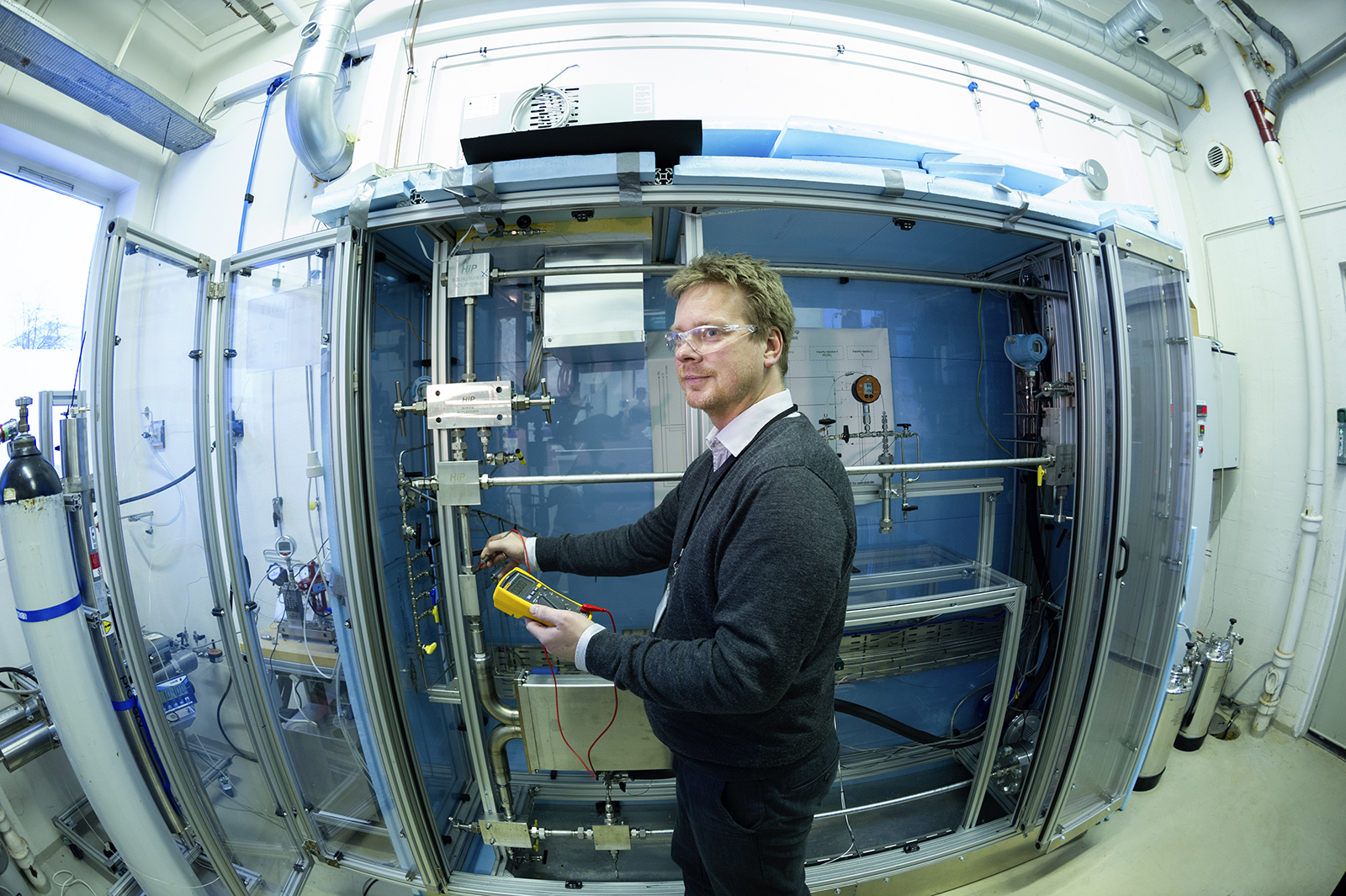

The Corrosion Technology department aims to understand and mitigate corrosion and corrosion-induced cracking in critical infrastructure.

Our focus areas:

- CO₂ Transport: Ensuring the integrity of infrastructure used for CO₂ disposal.

- Flexible Pipe Annuli: Addressing corrosion challenges within the annulus of flexible pipes.

- Multiphase Pipelines: Managing corrosion in pipelines that transport gas, oil, and water, particularly in the presence of CO₂ and H₂S.

Additional Efforts: Improving the regeneration of glycols used for hydrate inhibition and gas dehydration, and their potential to carry corrosion inhibitors