Mechatronics Engineering Group

From sensor to disk!

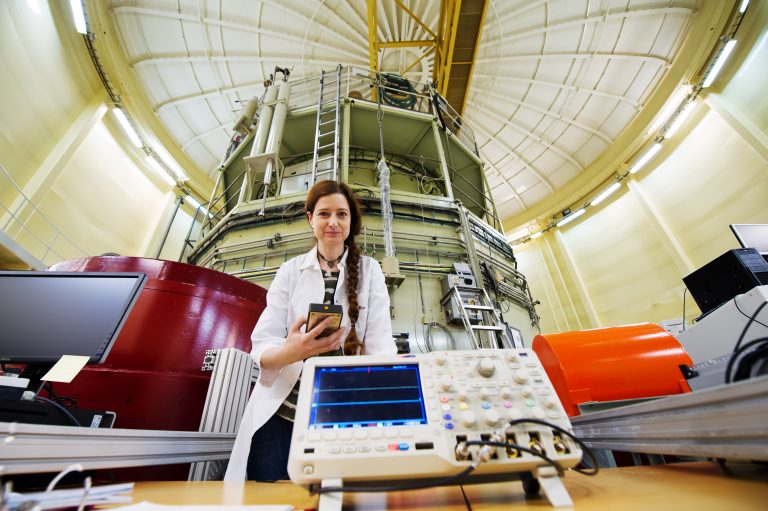

The Mechatronics Engineering Group has long experience in development and construction of instruments for industry and research purposes. We offer services in CAD design and drafting using SolidWorks. We have expertise in creating schematics for printed circuit boards using OrCAD Capture. We have long experience with integration of different solutions and creating tools and control systems using LabVIEW software development platform provided by National Instruments.

Below are few of the areas in which we can provide assistance:

Sensors and data acquisition

Data acquisition begins with the physical phenomenon to be measured. This phenomenon could be the temperature of a room, the intensity of a light source, the pressure inside a chamber, the force applied to an object, or many other things. A DAQ system usually consists of three parts:

- Sensors

- Measurement hardware

- PC with software for acquisition and control

Our expertise can help your project with interfacing sensors and actuators in your application. We have experience with:

- temperature

- pressure

- humidity

- flow

- valves

- various types of motors and motor controllers

- rotation stages

- motorized linear stages

- multi-axial platforms

- actuators

- controllers

- radiation detectors (neutron, gamma)

- multichannel analyzer (MCA)

- preamplifiers

Since no two experiments are identical the data acquisition system in most cases is going to be tailored to customer needs. There are many factors that will have to be considered when designing such a structure and our lab is ready to assist in setting up your future data acquisition system.

Questions?

Sensors and data acquisition: Iver Blix Loennecken

National instruments LabVIEW & Hardware

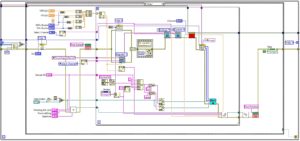

Laboratory Virtual Instrument Engineering Workbench (LabVIEW) is a system-design platform and development environment for a visual programming language from National Instruments

Originally released for the Apple Macintosh in 1986, LabVIEW is commonly used for data acquisition, instrument control, and industrial automation on a variety of operating systems, including Microsoft Windows, various versions of Unix, Linux and macOS.

It offers a graphical programming approach that helps visualize different aspects of your application, including hardware configuration, measurement data and debugging. This visualization makes it simple to integrate measurement hardware from any vendor, represent complex logic on the diagram, develop data analysis algorithms and design custom engineering user interfaces.

Currently we are in a process of building a software platform of standard libraries and tools most commonly used in projects at IFE that will further speed up process of software development. It will save time and provide tested and reliable code for different pieces of hardware. We also work with NI VeriStand – software that helps with configuration of I/O channels, data logging, stimulus generation and host communication for NI real-time hardware.

LabVIEW development environment is capable of integration different types of hardware from various vendors with different levels of ease. Moreover, National Instruments has a complete family of data acquisition products for desktop, portable, industrial and embedded applications. You can use NI-DAQmx driver software to integrate more than 200 data acquisition devices in LabVIEW on a variety of major buses and form factors, including USB, PCI, PCI Express, PXI, PXI Express, wireless and Ethernet.

In addition to data acquisition hardware, NI also offers other specialty test, measurement, and control hardware. Modular instruments synchronize measurements, signal generation, radio frequency (RF) and switching components for automated test systems. NI programmable automation controllers combine the ruggedness of a PLC and the performance of a PC for industrial measurement and control applications. Vision devices also offer unique capabilities not found in many traditional sensors, such as verifying component positioning, counting physical elements, and reading bar codes. Each hardware type includes its own driver software for easy integration into LabVIEW.

We have experience with a variety of HW provided by NI. From older models of Compact FieldPoint through various models of cDAQ, PCI I/O cards and PXI units to modern, high-speed cRIO variants.

Questions?

Nationa Instruments Labview Hardware : Iver Blix Loennecken

Electrical design

We also have expertise in solving wide range of electrical problems:

- Design of electrical circuits

- Design and building of electrical cabinets

- Troubleshooting

Questions?

Electrical design: Iver Blix Loennecken

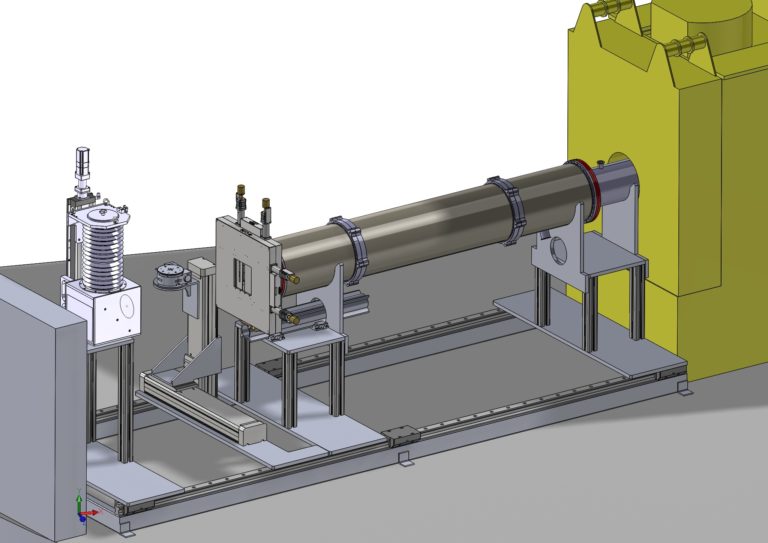

Mechanical design

In some cases customers require design and production of mechanical components for the instruments (mountings, shielding, tables etc.) we are able to assist with our experience in:

- CAD Design with SolidWorks

- Supervision of production

- Building of instruments

Questions?

Mechanical design: Jan Thomas Haraldsen

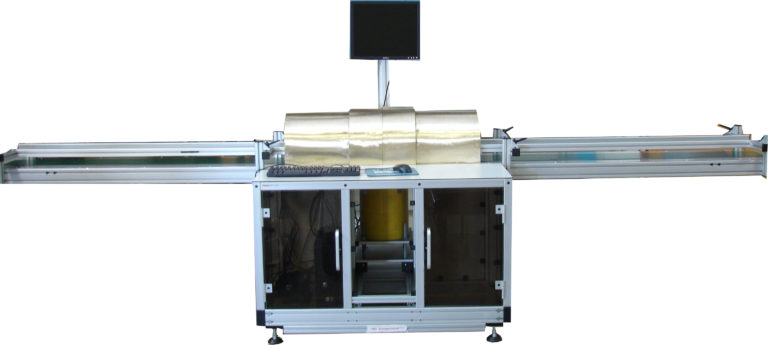

Instruments & tools

During the years electronic group was involved in multitude of different projects this has resulted in a number of custom designed instruments and tools:

- Hydrocarbon Core Scanner (HCS)

- Spectral Core Gamma Logger (SCGL)

- Residence Time Distribution (RTD)

- PCT

- Gamma densitometer (Fast Volume Weight Meter – FVWM)

- CO2 Flow Loop

- Well Flow Loop

Questions?

Instruments and tools: Mikolaj Kunc